Email to Us:Sales@welltechmold.com | Contact Us Today: +86 1392551 9842

Email to Us:Sales@welltechmold.com | Contact Us Today: +86 1392551 9842• WellTech WinMould – has a professional engineering team with rich tooling experience. Most of them are more than 10 years working experience.

Detail is the key to success. We have set up our own mold making standardization. The molds would be considered to built for maximized life and easy maintenance, minimum cycle time, reliably .

We also provide customer part design service. We gather customer’s idea and make into reality. Create the entire solution from design to production.

•Capability:

->Multi-Cavity Mold

->Stack Mold

->2K mold and Multi-Shot Mold

->Silicone injection Molds

->Gas Assisted Mold

->Zinc or Aluminum alloy die casting Mold

->Tailor make Part design and production

|

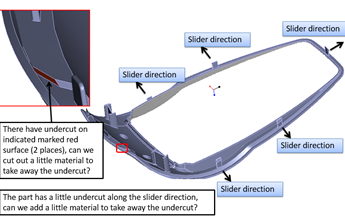

•DFM Reports DFM Reports are always made and sent out before ant tool drawings are started. This helps us make sure that our design would meet your requirement and be practical to your application. |

|

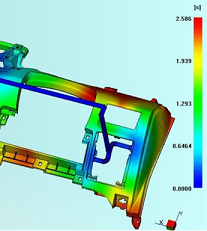

•Mold Flow Reports We use Mold Flow simulation software to evaluate the best possibility molding result with optimized gate and cooling . The distortion figure would be also given as evaluation. |

|

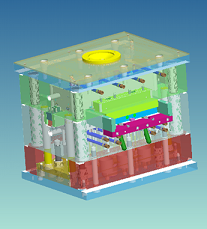

•Tool Drawing It normally takes 1 week to make tool design after DFM confirmed. The 3D tool drawing (stp format) would be sent to customer for confirm. The hard copy and soft copy of the latest tool drawing would be sent together with other inspection reports as manual when the tool is delivered. |